We offer 2-axis control upgrades for most Accurpress® back gauges, including the Accurpress® AP2.

#ACCUPRESS BRAKE MANUAL UPGRADE#

can help! Automec can upgrade existing press brake/ back gauge controls for less than 1/2 the price of purchasing a completely new system. As a result, you will get a great new system backed by a warranty and ongoing support. For example, Automec can utilize existing Accurpress back gauges and replace the obsolete Accurpress® AP2 with our CNC 150 or CNC 300 Press Brake Backgauge Control. The good news is that there are still third-party options for the Accurpress AP2. You need an ETS to use any of the Accurpress options described above. There are no Accurpress solutions for pre-ETS controls like the AP2.

#ACCUPRESS BRAKE MANUAL FULL#

The best solution may be a new third-party CNC control that comes with a warranty and full support. However, even if you can find an affordable used Accurpress control system in good shape, you will find no warranty and limited support for your used equipment. If your Accurpress has an ETS control station, you may be able to upgrade your control to any of the Accurpress models featured above. What are my options for Upgrading my old Accurpress CNC Control? While the Accurpress ETS200 control had the same look as the 100 – but included two-axis (X & Y) backgauge control with 100 onboard programs, nine steps per program, and a catalog screen. The Accurpress ETS100 Control worked with a Single-axis (X) backgauge control with 16 onboard programs, five steps per program. Accurpress ETS100 & ETS200 Controllers for single and two-axis backgauge controls. The ETS100 and 200 were mounted on the pedestal, and the ETS20 were mounted on the right side of the machine. While rudimentary compared with today’s modern press brake controls, these controls were sufficient to meet most press brake shops’ needs in the 1990s and early 2000.Īs an industry leader in press brake manufacturing, Accurpress offered several upgrades for CNC Gauging in the early years of ETS, from entry-level (ETS100) to its automatic multiple axis controls (ETS3000). Key switch to lock/unlock settings editing.The LCD panel displays the job program number (0 to 15), ram position high/slow/bend positions tonnage limit, ram delay at bend point, choice of inch or metric.Choice of either high position, slow position, or bend position for ram control.Push + or – keys (☐.001) for quick incremental changes.Three control modes: palm buttons only, foot switch only, palm/foot transfer.

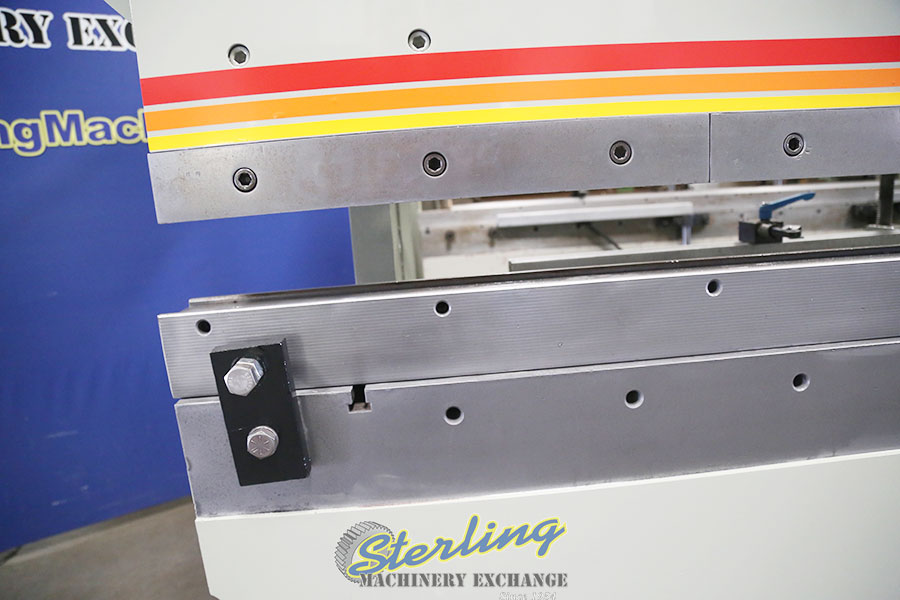

%201994%20Accurpress%20713012%20Press%20Brake%20-%20Pic%201.jpg)

The standard functions of the control included: The ETS was mounted on a pedestal incorporating a footswitch and dual palm buttons that gave the operator control over ram movements. The unit allowed storage of a total of 16 different bend programs in its memory. An LCD on the ETS showed the program details as text, and there were no graphic controls. The ETS programmable logic control (PLC) unit allowed press brake functions to be controlled by the operator through push-button controls over ram depth settings and tonnage limits. The ETS Pedestal Control was described as providing “All press brake functions at one station,” however, this is no longer an accurate description since it doesn’t provide CNC Gauging Controls that are a critical component for today’s modern press brake. The company provided a basic ETS pedestal control with all its press brakes. In the 1990’s, Accurpress upgraded to its ETS CNC Control systems.

0 kommentar(er)

0 kommentar(er)